Blog Post

12 Common Problems in Plants and Corrective Actions to Take

May. 31, 2023

Safety is no accident, but what does that really mean? It takes real work and planning to ensure hose and coupling safety. Accidents are caused by a variety of reasons, including insufficient training, lack of attention, cost, and reluctance to change. Yes, accidents happen, but the goal is to make them infrequent and minor.

At Dixon®, we understand the importance of putting safety first. That's why we've compiled a list of 12 common problems in plants and corrective actions to take to help reduce the potential for accidents.

Common Plant ProblemsDixon has traveled across the U.S. to conduct safety assessments and training at various plants, which has highlighted some universal problems. The photos and descriptions below can help show ways to improve the safety of hose assemblies, and, in many instances, conform to OSHA regulations.

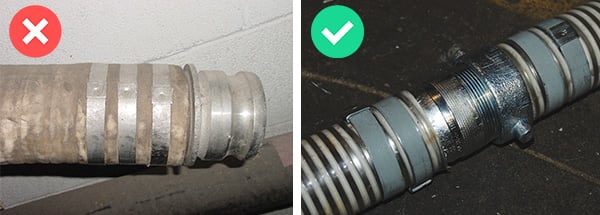

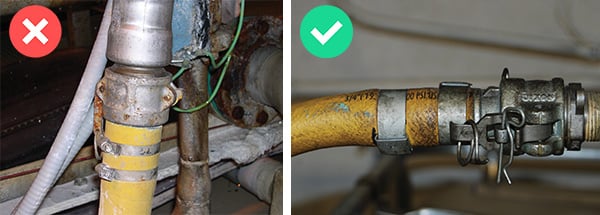

Band Clamps

Band-style clamps are a proven, effective method of retaining couplings in industrial hose. To ensure proper retention and sealing of the hose coupling it is imperative that the clamps be installed correctly. When installing multiple clamps, the buckles must be offset around the hose, eliminating the possibility of a straight-line leak under the buckle area. Please follow the manufacturer’s recommendations as to the proper selection and installation of band clamps.

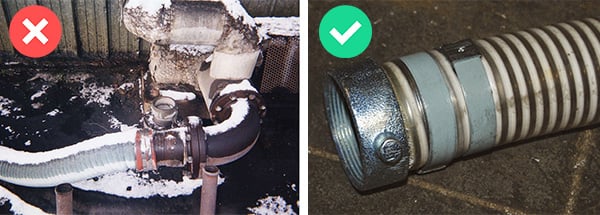

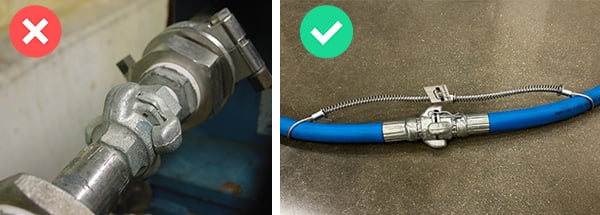

Steam Hose Connections

A sudden burst of steam can be extremely dangerous! Quick-acting style couplings should not be used in steam service, unless they are specifically designed for steam, such as Dixon MannTek dry disconnects for steam service, and HS-series hydraulic couplings. Otherwise, threaded union-style couplings such as Dixon Boss® couplings should be used. When a threaded union loosens under pressure, vapor will follow the thread path and provide a warning to the operator that the line is live, giving them time to safely re-tighten and re-seal the coupling.

With quick-acting style couplings, such as cam & groove or Air King® fittings, there is no vapor warning, and severe injury can occur.

Unsecured couplings can easily eject under pressure or vibration. Hose fittings are designed to be held in place by a clamping device such as a clamp or ferrule. An exception to this would be push-on fittings properly applied to push-on hose.

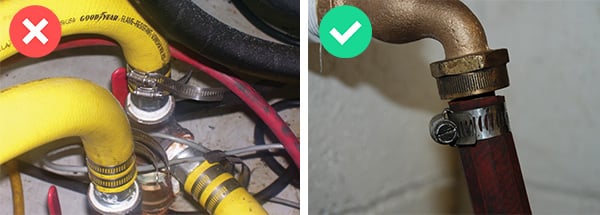

Worm Gear Clamps

Worm gear clamps are a good method of holding fittings in a hose in certain static, low-pressure applications, such as on a car radiator. This is why they are often referred to as radiator clamps.

However, worm gear clamps can be hazardous to equipment operators if the sharp, excess, extended tang material is left protruding from the clamp housing.

When a worm gear clamp is used care must be taken not to damage the cover of the hose. If the cover is damaged, the life of the hose is dramatically reduced. When a hose with a soft cover is used, a special liner clamp is available to protect the hose cover from damage.

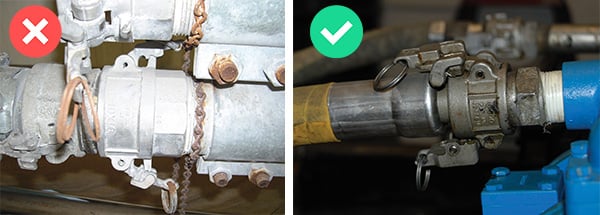

Cam handles must be completely down and in the closed position for cam & groove couplings to function properly. The pull rings on the handles should not be tucked under the arm as this will prevent the arms from totally closing.

Cam & Groove Handles

Two types of handles are commonly found on stainless steel cam & groove couplers: sintered stainless steel and investment cast stainless steel.

Sintered stainless steel handles are popular on many manufacturers' couplers. These handles are designed to withstand the abrasion that results from repeated connecting and disconnecting of the couplings. However, sintered (powdered metal) cam arms are prone to breaking when the assembly is dropped or dragged across the ground. If the handles are breaking, the more durable investment cast handles should be used. Investment cast handles can also be used as replacement parts on aluminum, brass, or unplated iron cam & groove couplers. Please ensure there is no product incompatibility prior to switching these handles.

Because various manufacturers of cam & groove couplings do not necessarily have compatible or interchangeable parts it is recommended that you purchase your replacement parts from the manufacturer of the coupling.

Using an Air King safety clip, or other wire-type retainers, is necessary to ensure that Air King universal couplings are properly connected and will not accidentally disconnect. The clips will not go through the holes in the mating fitting unless the couplings are fully locked in place.

Unsecured safety clips are often lost. Dixon offers a variety of lanyards to help keep safety clips close at hand.

Homemade blow guns seldom have the capacity to conform to maximum output specifications as established by OSHA. Please refer to osha.gov for a complete list of current regulations.

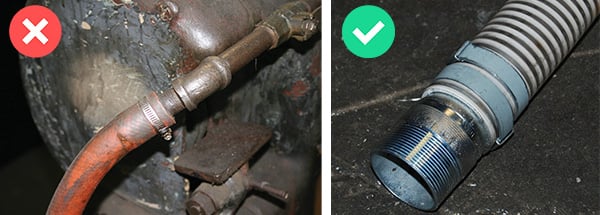

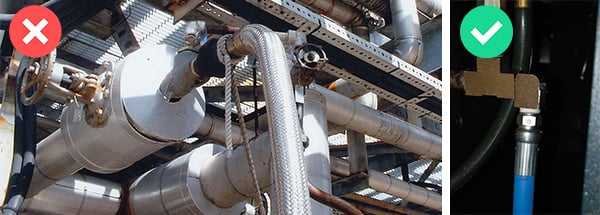

Common Pipe Nipples

Common pipe nipples should not be used as hose inserts. Industrial hose should instead be properly coupled with barbed or serrated hose stems designed to safely hold the fitting in the hose.

Smooth pipe nipples have no barbs or serrations on the body of the shank to safely secure them within the tube of the hose. Threaded pipe nipples will cut into the tube stock of the hose causing a premature failure of the assembly.

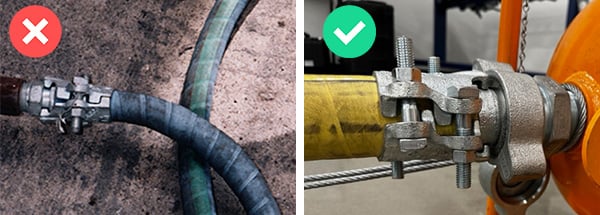

The proper selection, installation, and maintenance of bolt-style clamps are key factors in the safe performance of a hose assembly. The inside diameter and outside diameter of the hose are very important when it comes to selecting the proper clamp. The diameters must fall within the size range the clamp was designed to handle.

When installing a bolt-style clamp it is important to know that the individual body sections of the clamp should never be allowed to come in contact with each other. There must always be an even showing of rubber (hose) between the clamp sections for the clamp to be fully functional.

Bolt-style clamps can only fulfill their design capabilities if the bolts are tightened to their recommended torque. These bolts are designed to bend during the tightening procedure. They can be re-torqued, but it is not recommended that they be reused as they are designed for a single bend only. Do not replace old bolts with bolts of any other strength. These bolts are specifically engineered and are a designed part of the overall usability and function of the clamp. The clamp halves (Boss® clamp, double bolt clamps, and Air King clamps) are designed for a single bend only. When the clamp halves are removed from a hose they should be discarded immediately.

Wall and column outlets carrying pressurized media and hard piped in a position horizontal to the floor can be both dangerous and cost-inefficient. If a hose or coupling accidentally disconnects, a horizontal outlet would direct the flow of pressurized media toward the operator.

A horizontal outlet also causes undue stress on the hose since the tendency of the hose is to drape downward or vertically, which causes kinks in the hose immediately behind the fitting that can permanently damage the hose.

By inserting a pipe elbow at the outlet, the flow of an accidental disconnect is directed away from the operator toward the floor. The elbow also permits the hose to hang downward, in a natural state, thus extending its life.

Tape should not be used as a method of repairing hose. Tape, including duct tape and electrical tape, does not repair the hose; it merely hides the failed area. Proper repair methods should be used or the assembly should be removed from service.

Be SafeThe 12 items listed above are just some of the most common problems found in plants. Here are some additional guidelines to help you 'Be Safe' on the job.

For all hose assemblies in use:

Beware - Hose assemblies when used improperly or in the wrong application can be dangerous. The maximum working pressure shown on the hose is not an indication of the working pressure of the assembly. Based on the hose, fittings, and attachment method used, all assemblies should be permanently marked with the designed working pressure and the intended media. The assembly working pressure should be permanently displayed. Hose assemblies must be used for the intended service only. Never alter manufactured products or substitute component parts.

Eliminate - hazardous conditions by inspecting, maintaining, and testing hose assemblies. Dixon recommends that all hose assemblies be tested in accordance with the hose manufacturer's specifications. The application determines the regularity of the re-testing schedule.

Secure - inspect hose, fittings, clamping devices, and safety accessories before each use. Never take for granted that the coupling or attachment devices are properly installed.

Always - inspect and re-tighten the bolts of any bolt-style clamping device to the manufacturer’s torque specifications.

Fittings - hose and clamping devices that are worn out or damaged must be removed from service.

Educate - your employees about the proper use, care, and potential hazards of hose assemblies.

Dixon is committed to helping customers use products safely by offering a variety of distributor training programs.

In an effort to provide our customers with information regarding the proper and safe methods of assembling hose and couplings, Dixon offers Hose Coupling Workshops suitable for a company’s sales force and shop personnel. Classes consist of lectures and hands-on demonstrations of coupling selection, hose preparation, coupling installation, assembly testing, and maintenance procedures. This workshop is only available to authorized Dixon distributors.

Dixon On-Site Safety TrainingIn addition to Hose Coupling Workshops, Dixon, in partnership with your industrial hose supplier, is pleased to offer a hose and coupling safety survey of your plant, at no cost to you. This valuable program is designed to assist in your efforts to make your facility as safe, efficient, and productive as possible.

Today, plant safety is an enormous, ongoing endeavor in which it is impossible to be an expert in every field. The use of damaged or misapplied hose couplings and related items occurs. To the untrained eye, these hazards may continue to exist until an accident happens, threatening not only plant machinery but also the well-being of plant personnel.

Our program includes a visual inspection of hose assemblies and related accessories in your plant by Dixon personnel. A written, confidential report containing our observations and recommendations for corrective action is subsequently provided to augment your own ongoing safety program. If desired, photographs of the areas of concern can be supplied with the report. As a follow-up, the program offers an educational hands-on seminar directly relating to the safety concerns in your facility.

Plant safety is coming under increasing scrutiny by various regulatory agencies. Understanding the 12 most common problems found in plants and the corrective action to take can help prevent accidents and reduce the potential for safety violations and fines.

Let our trained personnel assist you in establishing and maintaining safety compliance in your plant with Dixon's On-Site Safety Training. Visit dixonvalve.com or call 877.963.4966 to learn more.

CA | en

CA | en